VIROCRUSH技術

To fulfill the customer’s demand for anti-bacterial and anti-virus products

MING FONG's VIROCRUSH technology was originally invested in research and development to solve customers' needs in medical industry for anti-bacterial and anti-viral products, to help reduce potential bacterial and viral infections that may be caused by the use of the product in the environment. After years of hard research and development, we formally completed the process development by the end of 2019 and go into mass production. We expect that VIROCRUSH technology can contribute to the global fight against the virus under the outbreak of Covid-19.

Today, VIROCRUSH technology aims to provide antibacterial and antiviral solutions for products in all walks of life, and to give products higher added value. The VIROCRUSH process technology has been proved by the ISO21702 international testing specification. The R value tested by the Japanese BOKEN laboratory is greater than 2, which is equivalent to 99.9% anti-virus, and it also meets the Japanese JISZ2801 inspection specification, up to 99.99% against harmful bacteria. VIROCRUSH technology can be applied to soft and hard plastic polymer materials, silicon rubber and tempered glass.

Starting in 2020, we will actively assist customers in customizing the anti-bacterial and anti-viral products, or introduce VIROCRUSH into customers' existing product lines, and we will strive to provide more diversified anti-viral services.

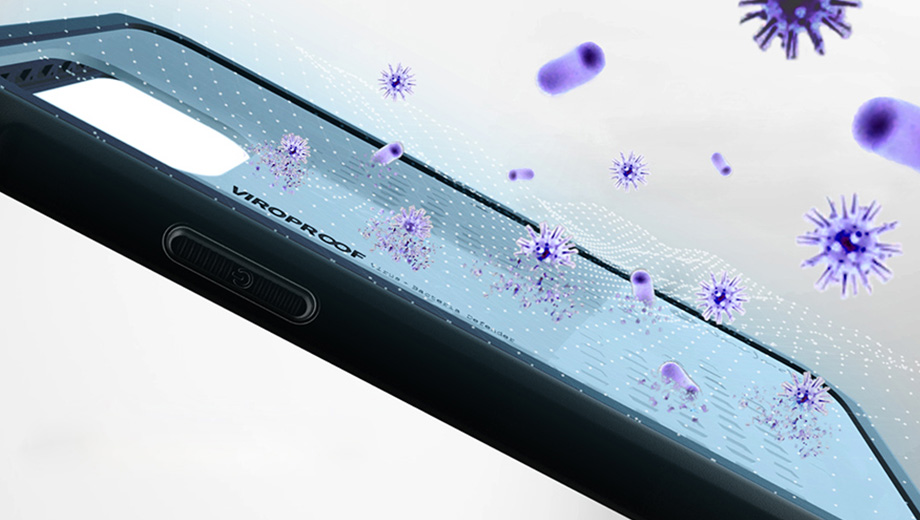

Highly Active "Free Radical" Nano-protective Layer

VIROCRUSH  Technology Mechanism

Technology Mechanism

After a special activation treatment on the surface of the product, a multi-national patented nanocomposite material is polymerized and introduced into the surface of the product by a special technology to form a layer of highly active free radical nano-protection. When bacteria fall on the surface of the product, the process of free radicals grabbing the charge will pull the cell membrane of the bacteria, making it unable to multiply and survive. Its redox process will make the bacteria and viruses inactive, thereby achieving the effect of inhibiting reproduction.

Applicable Materials for VIROCRUSH

(Soft&Hard Material)

The World's Leading Anti-Virus Technology

VIROCRUSH is a breakthrough antibacterial and antiviral process method designed to create long-lasting antibacterial and antiviral surfaces, and provides unique additional advantages in high-end technical solutions.

99.9% Antibacterial and Antiviral effect

Proved by ISO21702 Anti-virus Standard

Japan's Boken International Laboratory has verified anti-virus in accordance with ISO 21702 standards

Patented Nanocomposite Material

The patented nanocomposite material has been tested by US MICROBAC Laboratory and proved to be resistant to H1N1, enterovirus, and coronavirus up to 99.9%

99.99% Resistance to Harmful Bacteria

The independent testing unit has confirmed that it can resist harmful bacteria, such as Escherichia coli, Pseudomonas aeruginosa, Staphylococcus aureus

Day and Night, Continuous Protection

Does not rely on UV light, can last for a long time in natural light or darkness

Environment-friendly & Non-toxic

Nanomaterials have been certified by a number of testing units and medical centers to be non-toxic and non-allergenic

24/7 Long-lasting Defense.

Polymerized and embed the product surface in the process to achieve long-term defense

Provide Products with Higher Added Value

Uniformly Distributed

Different from the traditional method of adding antibacterial agents to the raw materials, VIROCRUSH can ensure the uniformity of the antiviral layer on the product.

Not Only Antibacterial, But Also Antiviral

In addition to pass a number of antibacterial tests, VIROCRUSH has been approved by international ISO antiviral standard!

Does not affect the thickness of the original product

VIROCRUSH technology is non-coated and will not increase the thickness of the product

Save manpower for repeated disinfection

Greatly save manpower for cleaning, because product in itself has already had antibacterial and antiviral capabilities

Not Only Antibacterial, But Also Antiviral!

In addition to pass a number of antibacterial tests, VIROCRUSH has been approved by international ISO antiviral stand.

| Standard | Testing Lab | Report No. | Testing Value |

| ISO 21702 Antiviral Measurement | Boken - JP | TW-2060018A | R=2.5 |

| ISO 21702 Antiviral Measurement | Boken - JP | TW-2060019A | R=2.3 |

| ISO 21702 Antiviral Measurement | Boken - JP | TW-2060015A | R=2.4 |

| Escherichia coli | SuperLab | M61-200300156 | >99.99% |

| Staphylococcus aureus | SuperLab | M61-200300157 | >99.99% |

| Pseudomonas aeruginosa | SuperLab | M61-200300158 | >99.99% |

| Escherichia coli | SuperLab | M61-200300159 | >99.99% |

| Staphylococcus aureus | SuperLab | M61-200300160 | >99.99% |

| Pseudomonas aeruginosa | SuperLab | M61-200300161 | >99.99% |

We sincerely look forward to cooperating with you and bringing more advantageous added value to your products!

_

_

_

_

_

_

Want to Know More about VIROCRUSH?